Effects

We focus on current demand in operational planning, not just forecasts, which leads to improved results

The system is suitable for various industries

Food and Beverages

Pet Food

DIY

Chemical Industry

Pharmacology

Cosmetics

Automotive

Metal industry

Building Materials

Packaging

Household Appliances

Clothing, Footwear, Accessories

Improve business efficiency and inventory management

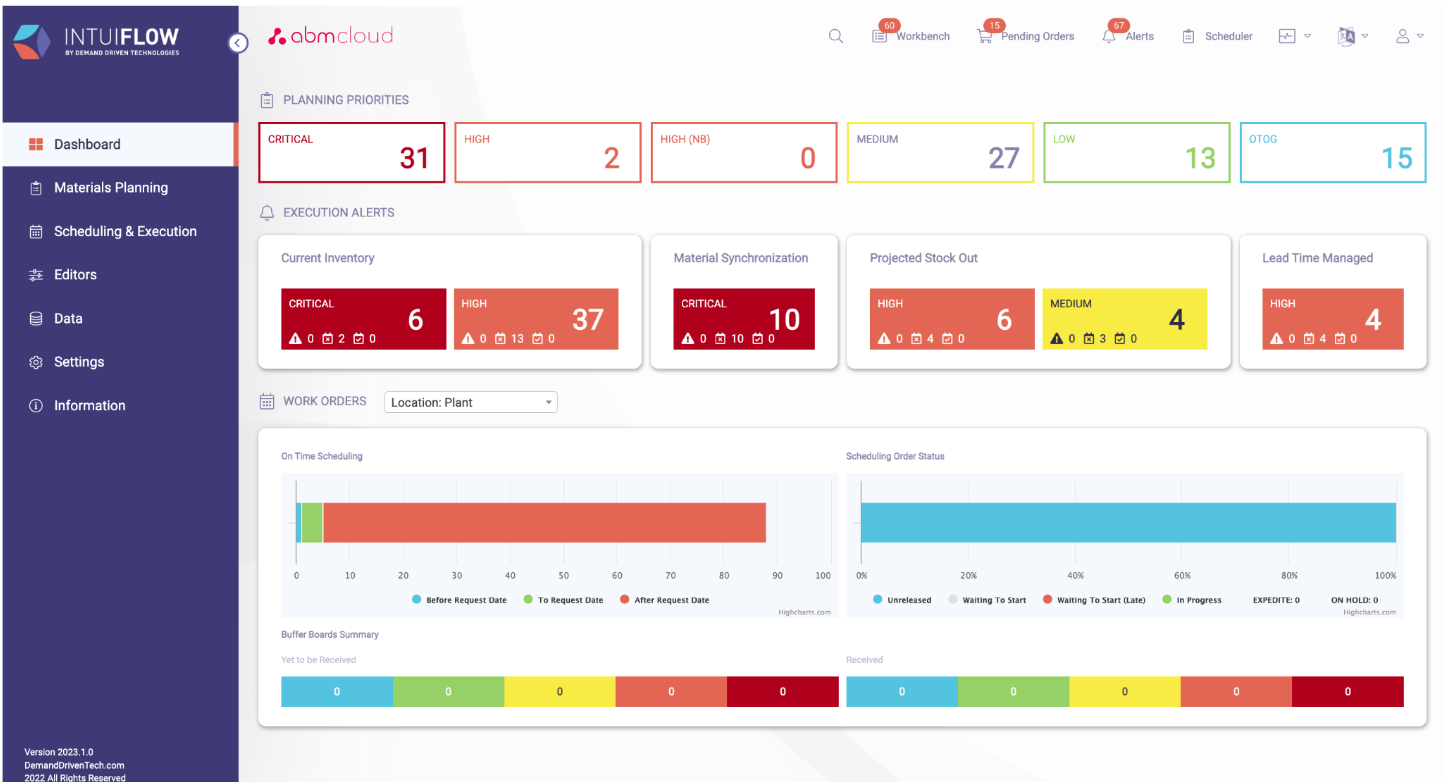

Dashboard

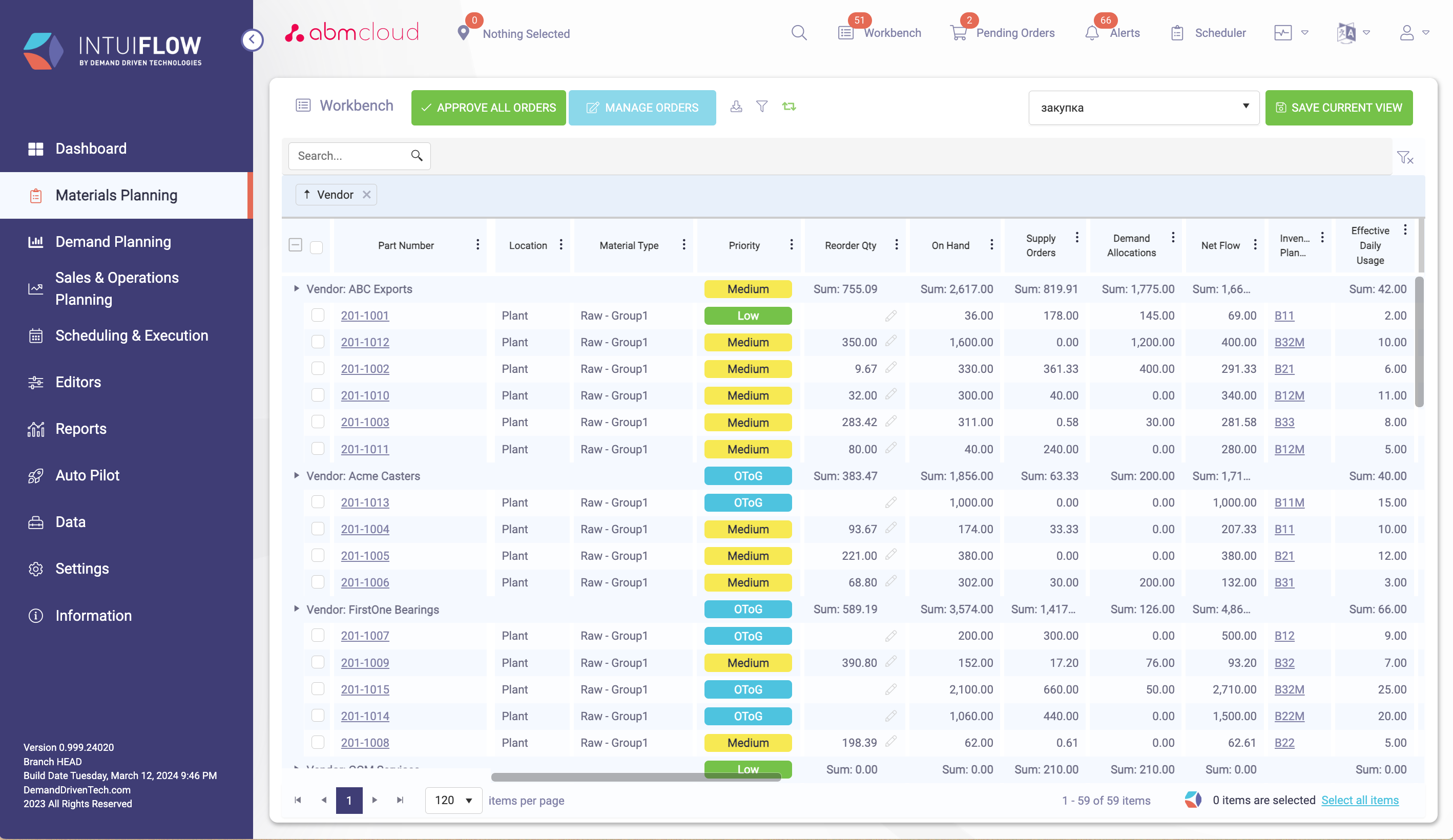

Purchase Planning

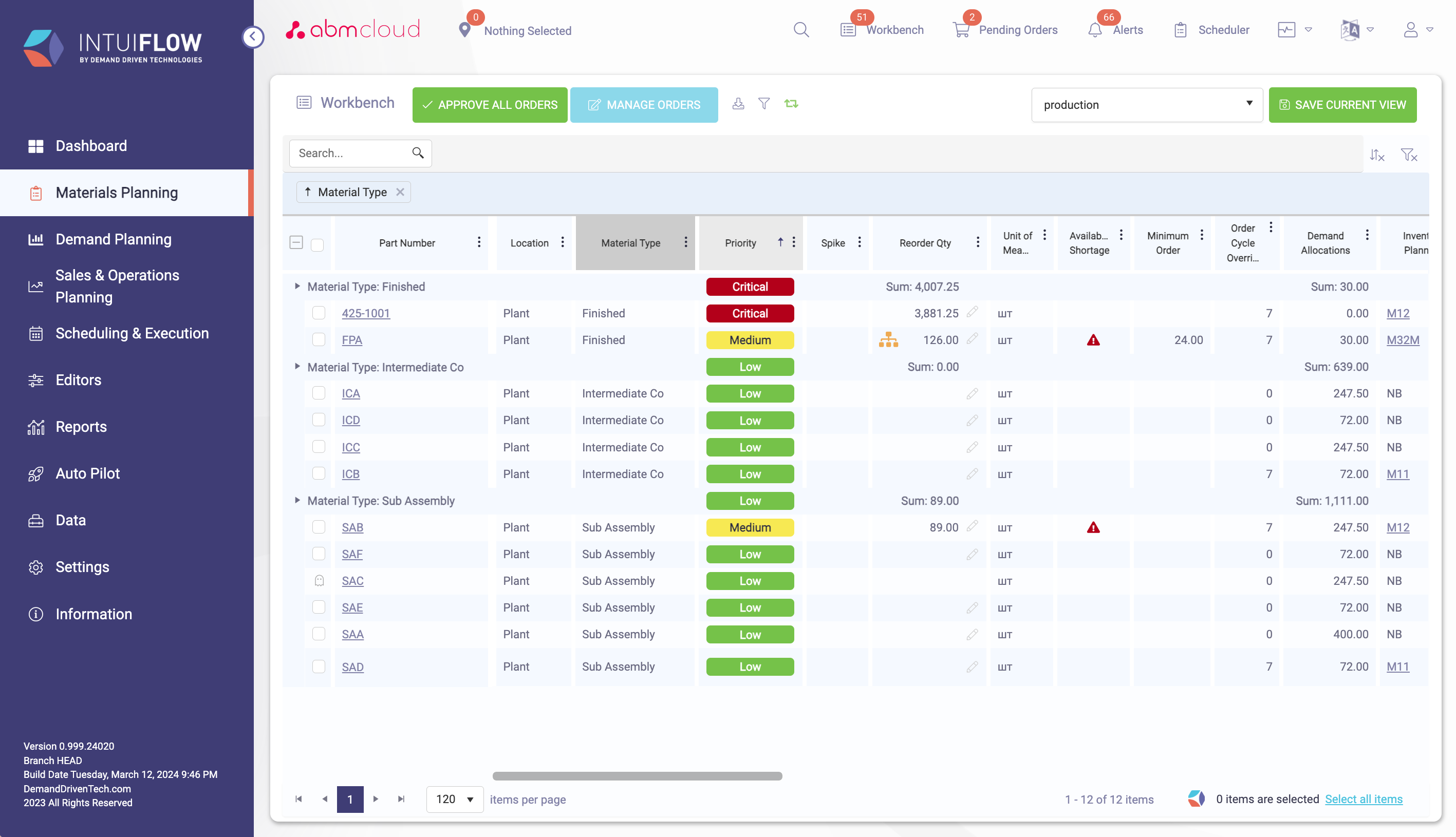

Production Planning

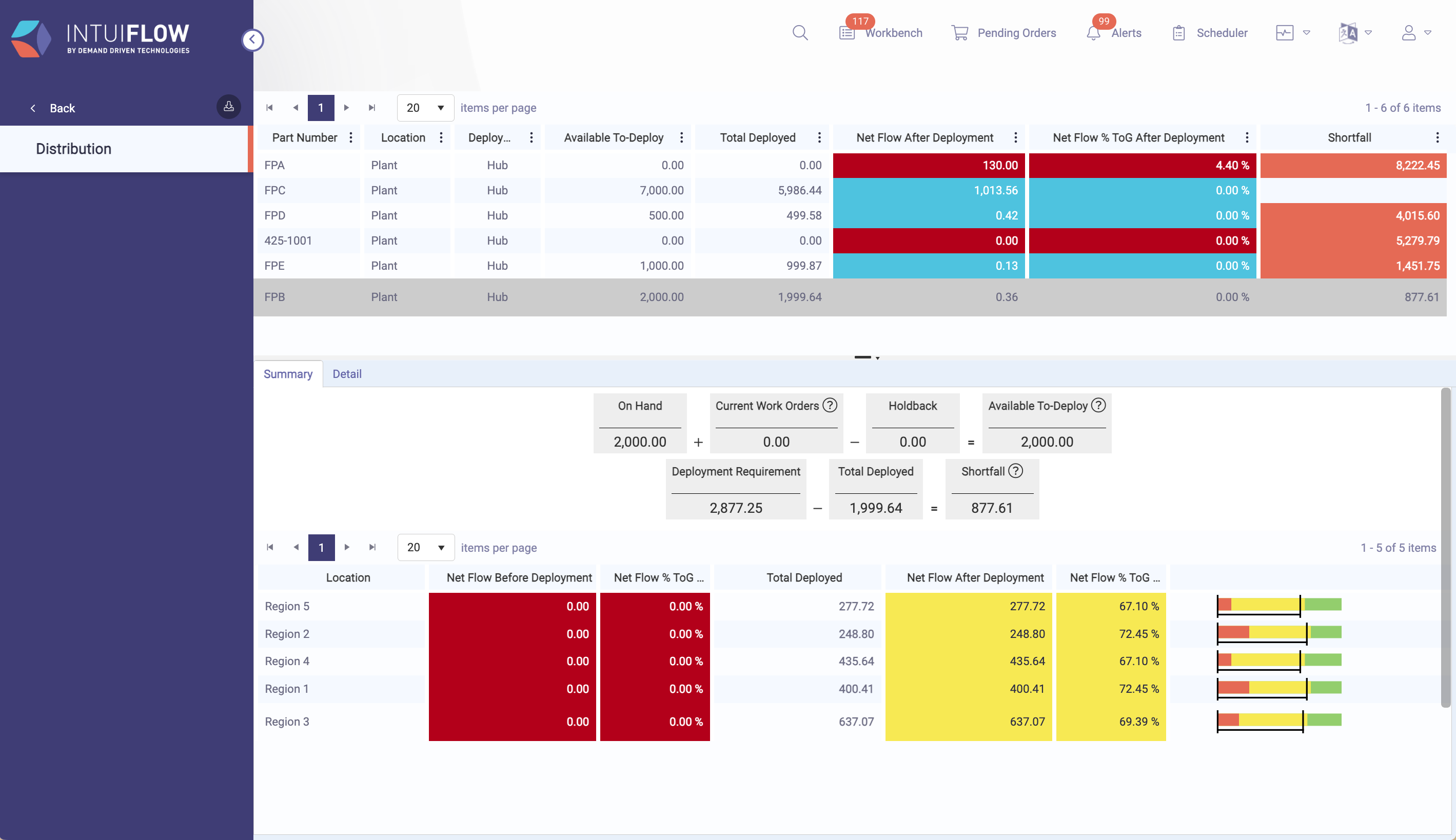

Distribution Management

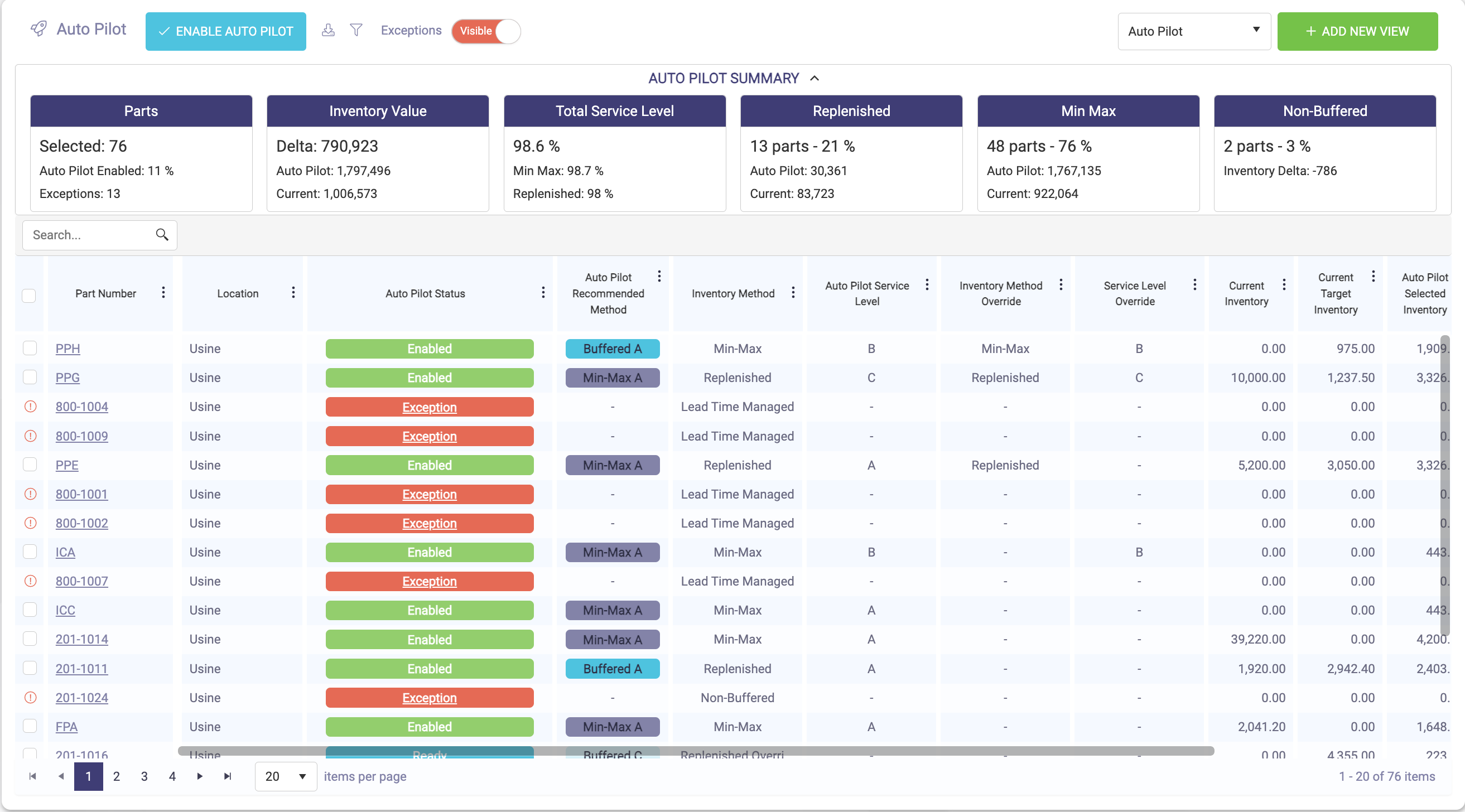

AutoPilot

Demand Planning

Sales and Operation Planning (S&OP)

Scheduling and Execution

PowerBI Reports

-

General information field

This is where planners manage their working day. Critical situations concerning stocks, orders, and overstocks are highlighted here.

-

Execution alerts

Situations that may arise after orders are approved, such as current inventory shortages, material synchronization processes, projected stockouts, etc. To resolve them, you have to make managerial decisions.

-

Tracking the status of the production

The manager can see the summary of work orders in real-time: their scheduling status, quantity, time and delays.

-

Automatic generation of the recommended order quantity

Systematic generation of order quantities based on the "Net Flow" equation and SKU-specific inventory management policy

-

Auto approving

Automatic approval of the system recommended quantity

-

The "priorities" system

Setting priorities allows you to easily evaluate what to focus on in the first place and account for the existing limitations of time, quantity, space, and capacity

-

Testing new inventory management models

Modeling capability: What average inventory will the system recommend if you change the cycle, minimum order, or other parameters? Prepare for a new season or promotions. How will the new supplier's work schedule affect your orders? Run the model with the new parameters of an alternative supplier or analogs. Create a new or modify an existing inventory management strategy, etc.

-

Automatic Generation of Order Recommendations for Production Planning

Systematic generation of order quantities based on the calculation of "flow balance" and inventory management policies for specific items.

-

Working with Items

Analysis of potential shortages, modification of components in specifications, adjustment of any item parameters, and the ability to model in case of changes in inventory management parameters.

-

The "priorities" system

Setting priorities allows you to easily evaluate what to focus on in the first place and account for the existing limitations of time, quantity, space, and capacity.

-

Workspace Customization

Managers can configure multiple individual "work views" to process: suppliers, countries, units of measure, product types, various classifications, and more.

-

Inventory allocation in distribution

The system will analyze and evenly distribute the available stock from your hub to all regions/warehouses in the network while considering their consumption and existing restrictions.

-

The system visualizes the replenishment of the stock buffer

and tells you how much is still missing per each warehouse.

-

AutoPilot

The feature is dedicated to generating optimal item level settings for Buffered and Min-Max items in Intuiflow. The key user input to the Auto Pilot is the target Service Level by inventory classification, i.e., A, B, and C items.

-

Demand History

Another key prerequisite for the Auto Pilot to run. Based on this input, the Auto Pilot runs simulations to generate the optimal buffer size recommendations that would enable you to meet your Service Level targets.

-

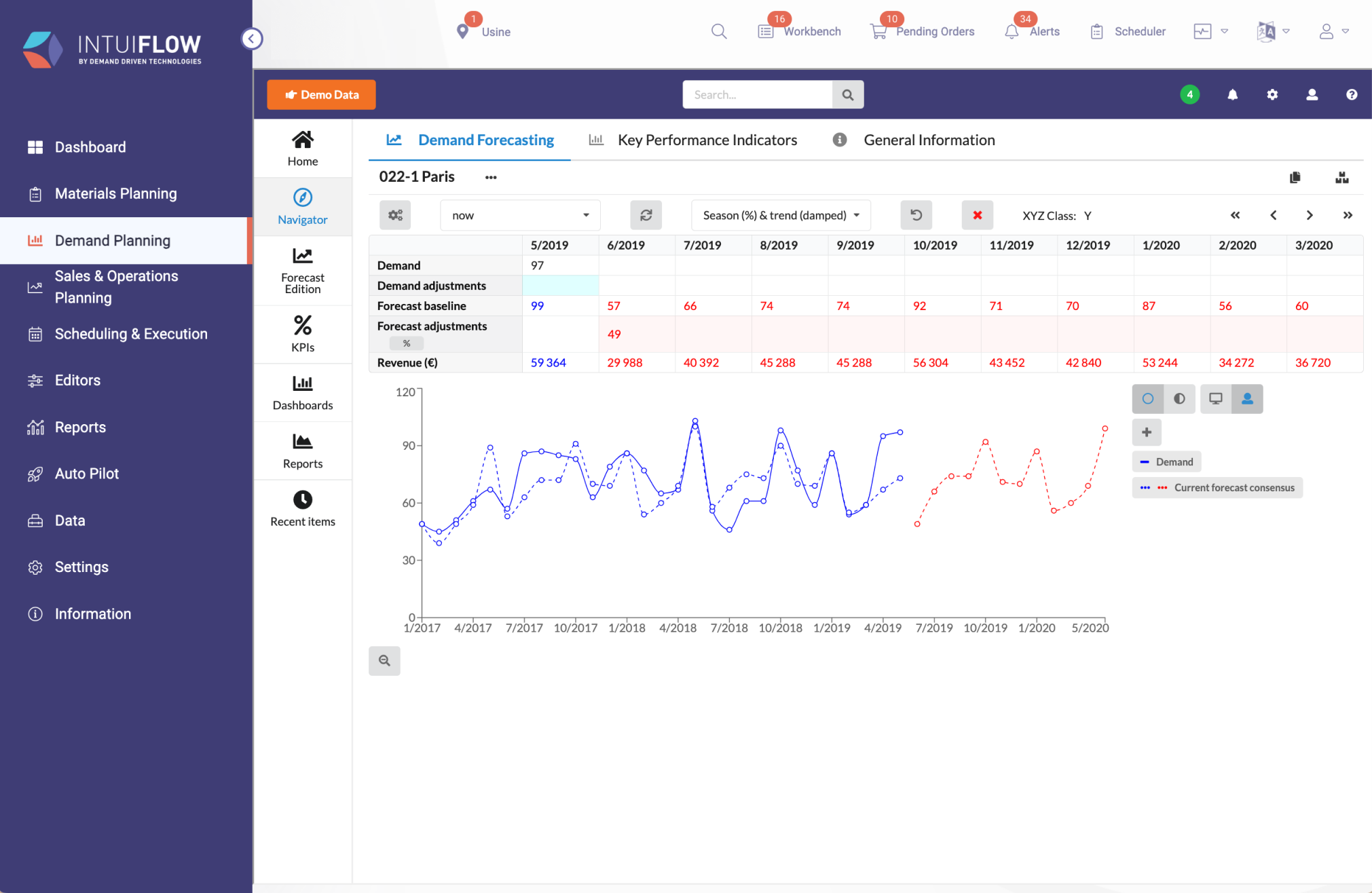

Accuracy and Bias

The system conveniently displays the accuracy of forecasts and the level of bias from actual data. This helps users understand how precise their forecasts are and whether they tend to overestimate or underestimate indicators.

-

Granularity and Horizon

Users can forecast at different levels of aggregation, from daily orders to annual sales planning. The system allows selecting the required level of granularity based on specific user needs.

-

Advantages of Forecasting

The forecasting block is valuable as it enables users to make precise forecasts at various levels of granularity and time horizons. Displaying accuracy and bias helps improve the quality of forecasts and make informed decisions considering the forecasted data.

-

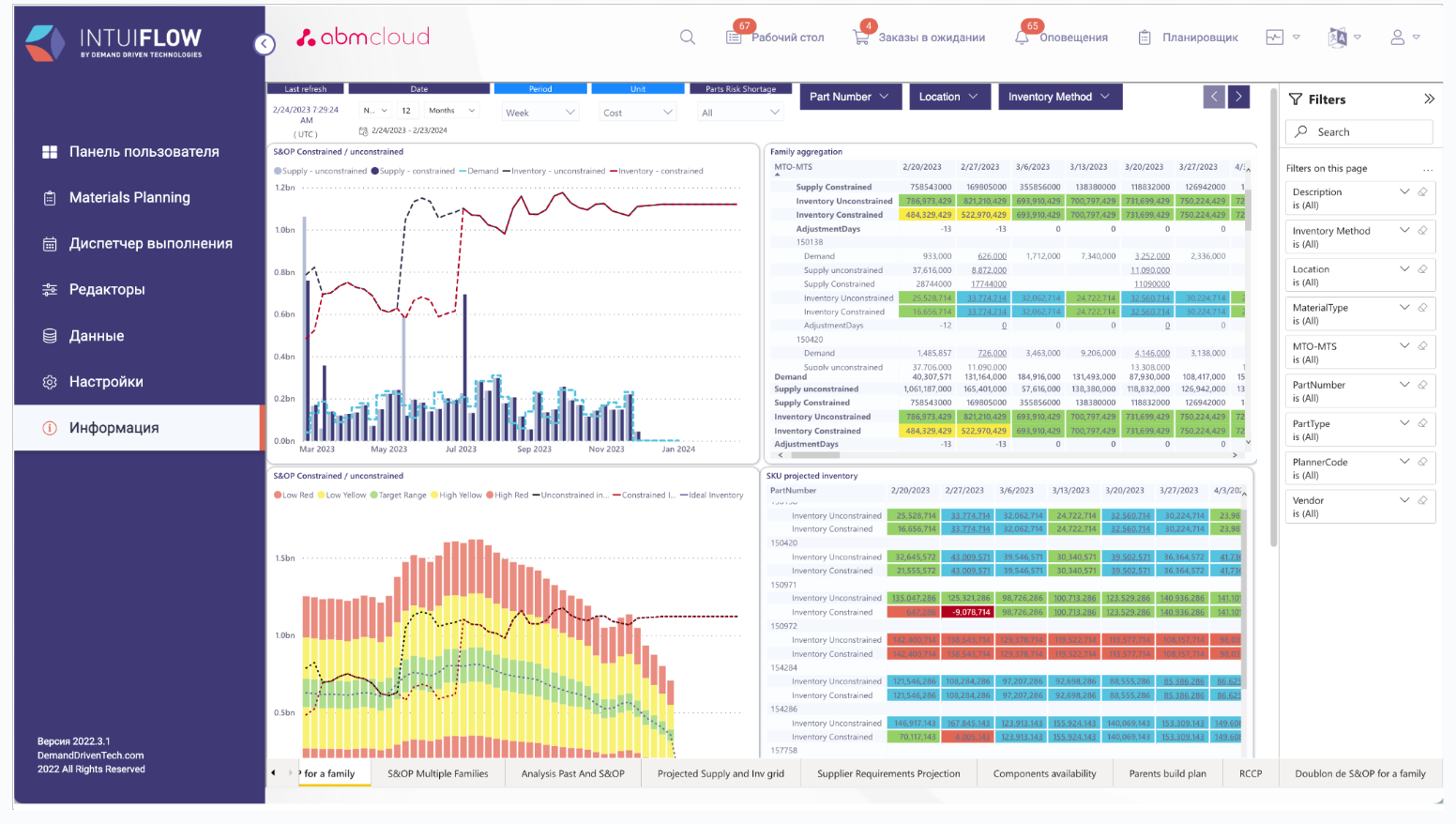

Sales and Operations planning reports

The reports will help you to develop tailored tactics. Build a model of the future strategy and compare it with the operational level.

-

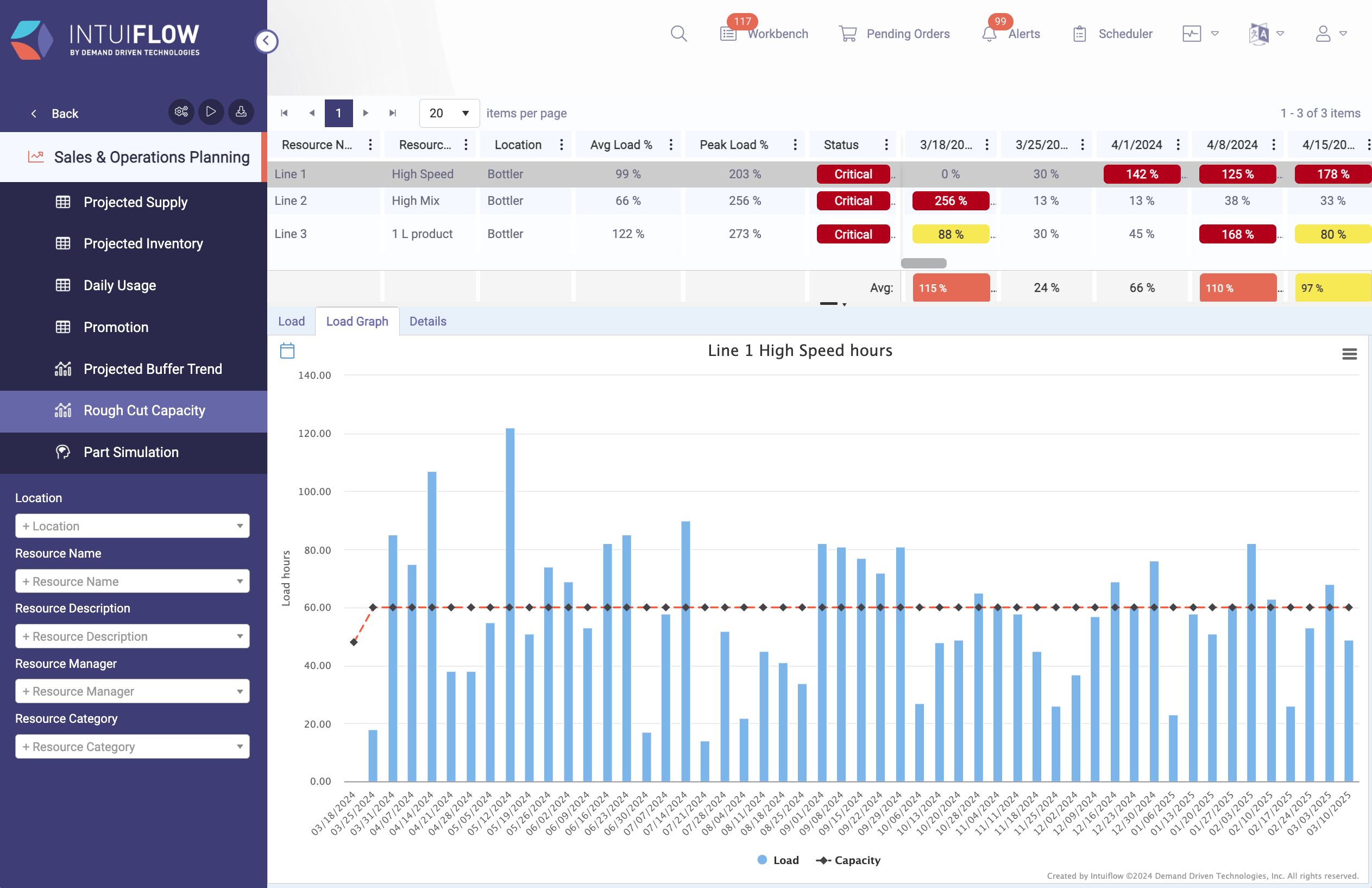

Rough Cut Capacity load chart

The chart simulates the projected capacity load based on your forecast and the orders generated from it.

-

Part Simulation

This is a tool that can help you run different scenarios for a specific part. Based on your forecast or demand history, the simulation will allow you to estimate the service level, SKU shortages, and average inventory.

-

Real-time monitoring

Monitor the current state of production facilities and each work order in real time.

-

Map your production flows

Identify bottlenecks to synchronize, analyze, and optimize production.

-

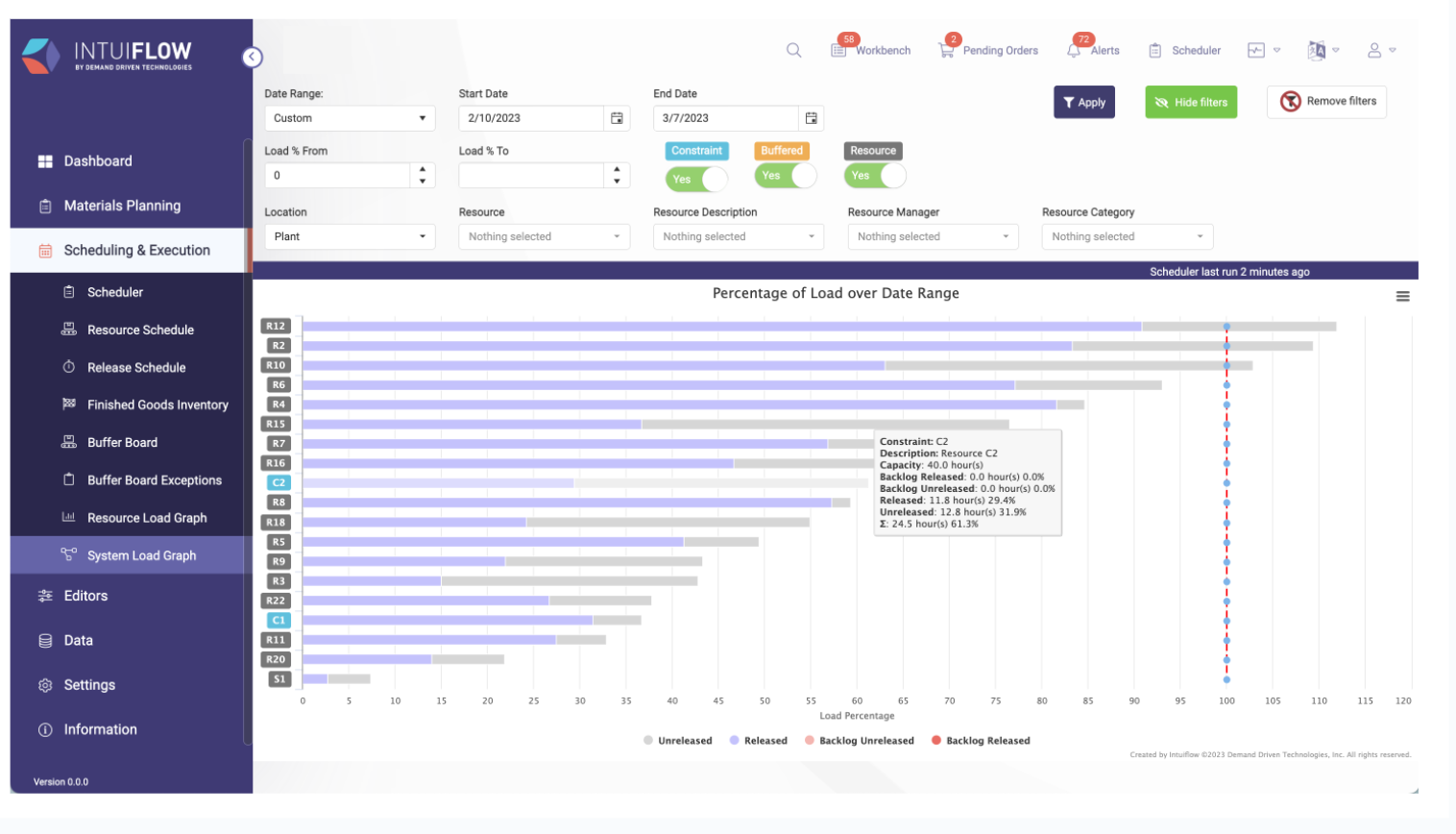

Monitoring the time load of each work center and shift

This is where you will find what orders are going into production, how much it loads the system and how long it is going to take as well as whether all production orders, for each of the work centers, have been taken up and completed on time.

-

System load graphs

These graphs provide extensive analytics and a transparent view of production facilities, both individually and for the entire system.

-

Analytics

Basic reports, as well as modern graphs and tables, are built based on the Power BI system to fit the needs of your team.

-

General dynamics of the inventory status

The amount of overstocks or out-of-stock and their dynamics over the period. The cost of your inventory. With the help of filters, you can drill down to the required level and locate the problem.

-

Dynamics of overstocks and out-of-stocks by managers

Reports generated by managers show where and who to focus on to achieve the desired results.

-

Power BI report designer

The designer helps you to create a variety of tables/charts/reports, etc., sorted by indicators such as supplier/warehouse/manager/order/stock or any other data.

How is the system implemented?

01 Express diagnostics

02 Training

03 Implementing the system

04 Support

Business Process Diagnosis and Data Collection:

Project Framework and Goals Analysis:

Identification of Missing Data:

Data Formalization and Update in Accounting System:

Team Identification:

Training Planning:

Internal Communication:

Basic Understanding of Methodology:

Integration Setup:

Data Preparation and Functionality Testing:

Industrial Exploitation:

Settings Optimization:

Technical Support:

KPI Monitoring:

Planners' Work Analysis:

System Update Training:

Your business results are our mission

Intuiflow software integration

We offer a comprehensive cloud-based inventory management solution that allows integration with various ERP systems. We also provide a user-friendly interface suitable for different industries

Automation of routine tasks for ordering

Shift the focus of managers' attention away from improving inventory management. We customize the optimal visibility of key factors for ordering for you. With transparent prioritization and alerts, it's easy to identify and respond to critical inventory situations

Built-in algorithms of the system's operation

These allow you to respond to demand trends, increase the company's efficiency, have a certain level of forecast accuracy. Inventory management should be simple and intuitive

High-quality support from Customer Success

After the implementation project, the client gets a manager whose task is to assist in improving the efficiency of the client's business. As a result of coordinated joint work on inventory optimization, overstock are reduced, shortages are minimized and the ordering process is improved

Increased business profitability

One of the effects you achieve with our solution is an increase in ROI and service levels because materials and finished products are available at the right place, in the right quantity and at the right time

Analytics

We offer order management and complex analytics (Power BI reports) among the core functions of the system. We promise to improve your team's decision making with Intuiflow's robust reporting.

We appreciate that you are interested in our products. One of our staff will be in touch with you shortly. Have a great day!